Robotic Electric Torque Control Automatic Screwdrivers

Robotic electric torque control automatic screwdrivers Specifiation Functions&Advantages Functions. 1. Wide universality

Basic Info

| Model NO. | TBS-SM-6331C |

| Power Source | Electricity |

| Function | Professional |

| Condition | New |

| Customized | Customized |

| Feeding Type | Pick and Place |

| Transport Package | Plywood |

| Specification | 900*650*880mm |

| Trademark | TOPBEST |

| Origin | China |

| HS Code | 8479899990 |

| Production Capacity | 200 Sets Per Month |

Product Description

Robotic electric torque control automatic screwdrivers

Specifiation

| Model | TBS-SM-6331C |

| Machine Size | 900*650*1100MM,Packing size:1000*750*1270MM |

| Weight&Packing | 15.KG,Plywood Packing,total 190KG |

| Power supply | AC110V/220V, 50HZ/60HZ |

| Air pressure requirement | 0.4 to 0.8 Mpa |

| Move speed | X,Y 600-800MM/S,Z 400MM/S |

| Control System | Touch panel |

| Driving mode | Closed-loop motor + synchronous belt |

| Alarm system | Screw stripped and loose alarm |

| Screwdriver Brand | KILEWS/SD |

| Feeder Brand | TBS |

| Torque Range | According to product |

| Feeder capacity | According to screw size |

| Feeder mode | Pick and Place |

| Repeated accuracy | ±0.02mm |

| Fastening efficiency | 40-60 PCS/Min |

| Max. load | 15KG |

| Work environment | Temp 0~40ºC,Humidity 20%~95% |

Functions&Advantages

Functions.

1. Wide universality, small in size, can cooperate with production line, convenient for product replacement.

2.With intelligent inspection function, inspection miss locked,unstable locked,loose screw and so on.

3. The Y axis can be made into double-station(that is, double Y axis),so the operator can load alternately.

5. High degree of automation, easy operation which the staff can master and debug quickly.

6. Accurate torsion, convenient adjustment, and the quality of lock is guaranteed.

7. Touch screen display or teach pendant programmable achieve more operations,Through a simple programming, can be put into production, convenient for production and management.

8. With the function of leak detection, once a screw did not fill in place it can fill continually or start alarm processing.

Advantages.

Reduce cost:High-efficiency operation is achieved by only one person.one person's efficiency amounts to 3-5 persons' efficiency

High efficiency:the number of electric screwdriver of the Z axis is customizable according to customers' requirements. Several electric screwdrivers can work at the same time.

More relax: single equipment for single worker, Just finished loading,Reduce the labor intensity of workers.

Reliability:Automatic alarm system, working >20 hours

Good image:Iintelligent automatic equipment presents a new appearance of production line in factories,which helps enterprises establish a image of high technology

6.Customization:Robot can be customized based on customers' requirements on products assembly.

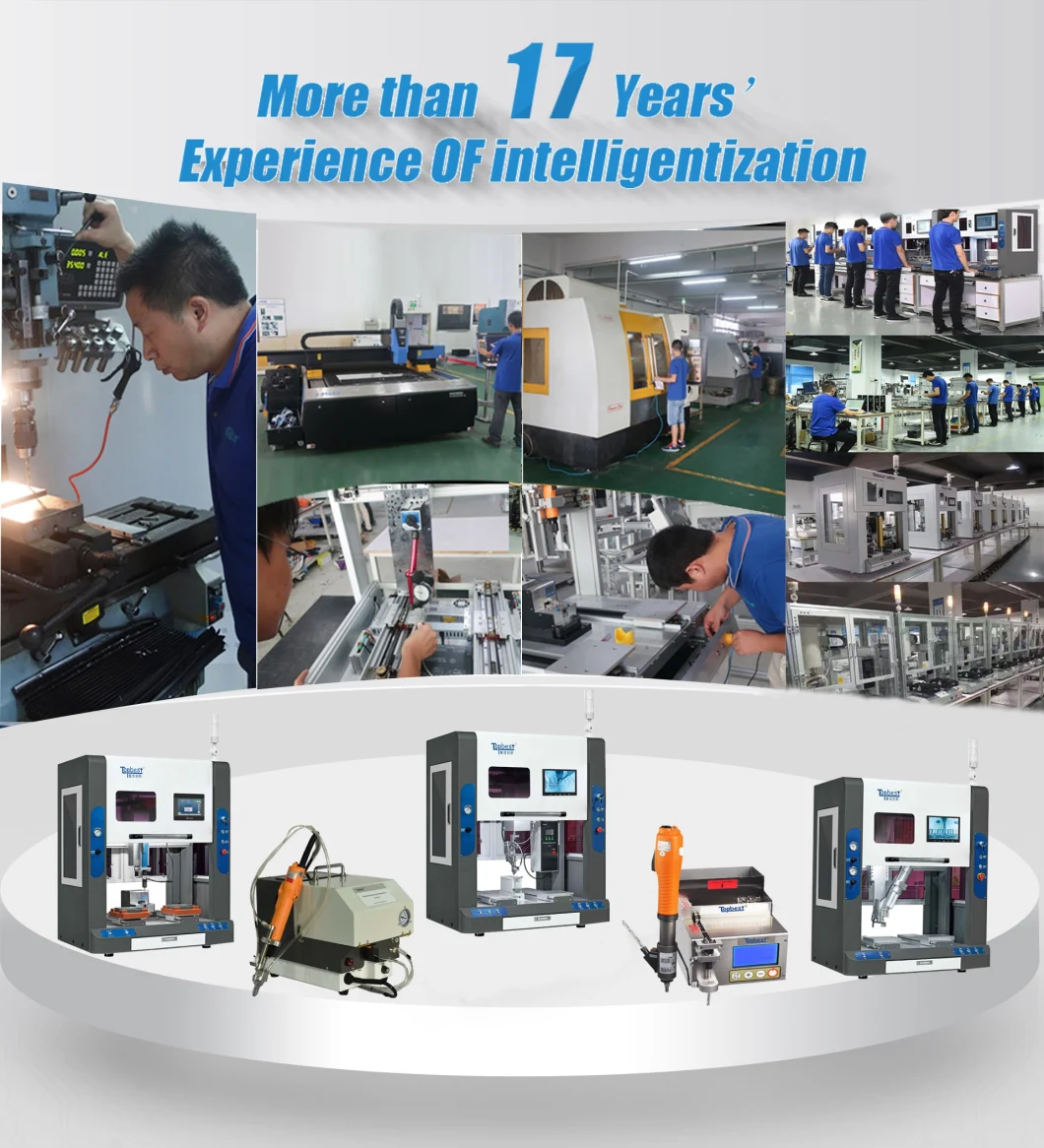

Certificate Display

Customer Visit

We have own factory and skilled workers,rich-experienced design team and good after service. We are a professional sales team with high efficiency, and endeavoring to provide satisfactory services to every of our customers as always.

Nearly every day from customers and abroad come to our factory, we arrange technicians to show the machine operation. Free training is available. Warmly welcome you to visit our factory!

Send to us